GSA Certified Safe and Vault Technician versus "GSA certified"

Recently there have been numerous cases that have come to our attention of safe and vault technicians claiming to be "GSA certified" throughout the northeastern US without any of them having completed the required "GSA Certified Safe and Vault Technician" course which can only be achieved by attending one of two training facilities in Nicholasville, Kentucky. These two facilities are MBA USA and Lockmasters Inc.

The "GSA Certified Safe and Vault Technician" course is not only expensive for the average safe and vault technician or locksmith to attend but adding in the costs associated with travel to one of these two facilities, lodging, meals, and time away from their own business to complete the certification course most will simply not invest in the education the "GSA Certified Safe and Vault Technician" course demands. So, they claim to be "GSA certified".

What does "GSA certified" mean? Maybe they've "been working on GSA safes and vaults for 35 years..." and "know what they're doing"??? Maybe they took a single GSA Approved lock manufacturer's class a decade or two ago and are claiming they're "GSA certified"??? Maybe they've never taken a single educational course through any educational facility, anywhere, and still claim they're "GSA certified". They're NOT.

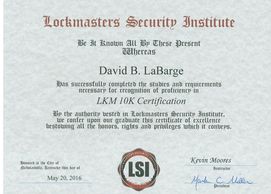

All of these types of "claims" have been heard throughout the northeastern United States and the entire country. A "GSA Certified Safe and Vault Technician" should be willing to provide proof of the completion of the GSA Certified Safe and Vault Technician course including a copy of their GSA certification certificate. To determine whether your "GSA Certified" safe and vault technician has actually completed the course you may contact each facility directly.

Their toll free contact info is:

MBA USA 1-888-622-5495

Contact info: www.mbausa.com

Lockmasters Inc 1-800-654-0637

Contact info: www.lockmasters.com

Many so-called "GSA certified" safe and vault technicians unnecessarily damage or destroy GSA security containers, safes or vault doors by using improper opening and repair methods or do not repair the damage to Federal Standard 809D leaving the end user without an approved location to store their National Security Information. This type of "service" ends up costing the customer much more than if the work was properly performed in the first place by a competent technician who has completed the GSA Certified Safe and Vault Technician course.

Opening and repair services performed by a GSA Certified Safe and Vault Technician may be priced higher due to the costs associated with attaining the certification but isn't an educated safe and vault technician worth it?

There's an old saying: "If you think it's expensive to hire a professional to do the job, wait until you hire an amateur!"

Find us on Facebook on these pages:

GSA Certified Safe and Vault Technician

and

GSA Inspector

GSA Certified Safe and Vault Technician Info

GSA Certified Safe and Vault Technician

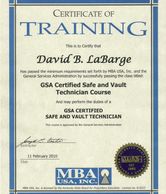

Dave LaBarge of LaBarge Lock and Safe Technicians is a GSA Certified Safe and Vault Technician providing GSA Approved safe and vault openings, repair and lock installation services per Federal Standard 809D throughout New York state and New England.

We've been providing these type of professional safe and vault services since 1986.

Kaba Mas X-10, X-09, X-08 & X-07 Factory Certified

We are a Kaba Mas factory certified technician and installer for the complete line of GSA Approved electromechanical combination locks meeting Federal Specification FF-L-2740B for the storage of "NSI", National Security Information.

If your storing "classified information" these type of locks are required per FF-L-2740.

These locks are NOT intended to be used for weapons, keys or valuables storage.

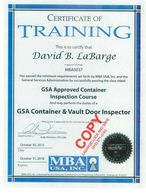

GSA Container and Vault Door Inspector

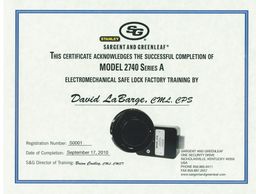

Sargent & Greenleaf 2740A & 2740B Factory Certified

Every security container, safe & vault door used by the U S Military and government agencies must have a "GSA Approved" label affixed to it to store National Security Information.

If the GSA label is missing the container can only be used if it passes a mandatory "re-certification" exam and only then can the GSA label be replaced allowing it to be used.

Dave LaBarge has been a GSA Certified Safe and Vault Inspector continually since 2003 performing inspections throughout New York state and New England.

Sargent & Greenleaf 2740A & 2740B Factory Certified

Sargent & Greenleaf 2740A & 2740B Factory Certified

Sargent & Greenleaf 2740A & 2740B Factory Certified

LaBarge Lock and Safe Technicians is a factory certified technician and installer for the Sargent & Greenleaf 2740A and 2740B series of GSA Approved combination locks meeting Federal Specification FF-L-2740.

Sargent & Greenleaf 2890B Factory Certified

Sargent & Greenleaf 2740A & 2740B Factory Certified

Lockmasters LKM7000 and LKM10K Factory Certified

Used for sensitive SCIF environments, the S&G 2890B provides single motion egress from inside secure rooms. It provides security and life safety at military bases and defense contractor sites.

The S&G 2890B may be used with either the S&G 2740B or the Kaba Mas X-10 locks.

We are S&G 2890 factory trained technicians with installations throughout New York state and New England.

Lockmasters LKM7000 and LKM10K Factory Certified

Sargent & Greenleaf 2740A & 2740B Factory Certified

Lockmasters LKM7000 and LKM10K Factory Certified

We are a Lockmaster's factory certified technician and installer for the LKM 7000 and the recently GSA approved LKM10K Pedestrian Door Deadbolt locks meeting Federal Specification 2890B.

We can also supply parts and repairs for the LKM 7000 and LKM10K Pedestrian Door Deadbolt locks.

GSA Approved Safe and Vault Services

Locked Out of your Security Container/Files---We Expertly Open and Repair DoD Equipment

Locked Out of your Security Container/Files---We Expertly Open and Repair DoD Equipment

Locked Out of your Security Container/Files---We Expertly Open and Repair DoD Equipment

Occasionally a GSA security container, which look similar to a file cabinet with a combination lock installed on it, has lock problems. Lost combinations, defective locks, broken handles or jammed boltwork are only a few of the problems security equipment can develop.

We offer both "Open Only" and "Open and Repair" types of services. We can professionally open and repair your container according to Federal Standard 809D.

We sell GSA safe and vault parts including handles, safe locks and dials, and much, much more!

We also offer GSA security container disposal services for our customers.

BLACK LABEL SECURITY CONTAINER

PHASE OUT PLAN

Starting in October 2024 Class 2 Black label security containers are no longer approved to store classified information.

On October 1, 2025 Class 3 & 4 Black Label security containers can no longer be used.

On October 1, 2028 ALL Black Label security containers are no longer approved including Classes 1, 5, and 6 security containers.

Vault Door Servicing

Locked Out of your Security Container/Files---We Expertly Open and Repair DoD Equipment

Locked Out of your Security Container/Files---We Expertly Open and Repair DoD Equipment

GSA Approved vault doors should be serviced every two years or problems could develop with the operating mechanism without such servicing. Any noticeable problem should be checked out before a lockout occurs.

GSA Approved vault door lockouts can be expensive in some cases so its better to have it checked out now rather than be locked out later. If an unknowledgeable or uncertified locksmith attempts opening a locked vault expensive damage could occur leading to vault door replacement at a cost of $25-35K or more.

Vault Door Lockouts

Locked Out of your Security Container/Files---We Expertly Open and Repair DoD Equipment

Map & Plans and IPS Containers

While a GSA Approved vault door lockout is a rarity, they do occur. Whether the problem is the combination lock or the Class 5 vault door's operating mechanism we can professionally open your locked vault door.

Afterwards, we can restore the vault door to it's original integrity allowing it to be used again for security (5S), armory storage (5A), or ballistic (5B) purposes.

We install Sargent & Greenleaf 2937 mechanical safe locks on

Class 5 Armory vault doors and Kaba Mas

X-10 electromechanical safe locks for security vaults.

Map & Plans and IPS Containers

We Service New York state and New England

Map & Plans and IPS Containers

While they look like your average safe, Map & Plans and IPS safes, (Information Processing System Storage) containers store electronic computer systems, servers, data communications equipment and data storage devices. They are expensive to replace and very time consuming to move and set-up if not opened professionally and then repaired by a GSA Certified Safe and Vault Technician.

Dave LaBarge, of LaBarge Lock and Safe Technicians provides professional opening and repair services on GSA Approved Map & Plans and IPS containers.

We also service DoD Field Safes, Special Purpose safes and containers, COMSEC safes, and provide installation services for CDX-10 Pedestrian Door Deadbolt locks for SCIF areas and secure SCIF rooms.

Don't let an unqualified person try to service or open your high priced security equipment. It could end up costing you much more when your security equipment has to be replaced due to an unknowledgeable incompetent technician.

We Service New York state and New England

We Service New York state and New England

We Service New York state and New England

We offer our GSA Certified Safe and Vault Technician services throughout New York state, New England and some of the mid-Atlantic states.

If you have a GSA equipment safe or vault door related question feel free to call us anytime at 518-271-0783. Most calls are immediately answered but since cell phones are not allowed in certain locations if you receive our voice mail please leave a message and we'll return your call as soon as possible.

We've provided professional GSA safe and vault services in the above areas for the following branches and agencies:

National Guard, Air National Guard, US Army, US Marines, US Air Force, US Navy, US Coast Guard, DEA, FBI, US Secret Service Homeland Security, US Marshals Service, US Customs and Border Protection, as well as many regional and northeastern United States locations for Department of Defense and Department of Energy government contractors.

GSA Approved Safe and Vault Manufacturers

We Service New York state and New England

We Service New York state and New England

Many manufacturer's have made GSA Approved safes, security containers and vault doors since the 1950's. We service all from the following companies:

Alpha Safe & Vault

A&H Security Cabinets

American Made Safe & Security

Armor Safe Corporation

Art Metal USA

A&H Security Cabinets

Brown Safe Manufacturing

Diebold Inc.

FedSafes

Hamilton Products Group

Herring Hall Marvin

Hillside Metal Products

International Vault

LeFebure

Merritt Industries

Mosler

Mosler-Diebold Security

Overly Door Company

Schwab Safe Company

Trusted Systems

Will-Burt Company

What Happens When You Get An In-Experienced "SafeTech"

Experience and Certifications Count!

GSA Approved Map & Plans Repair---NOT!

GSA Approved Map & Plans Repair---NOT!

Many locksmiths and safe technicians are unfamiliar with the standards set by the federal government for the opening and repair of expensive security equipment. They arrive on-site without the proper knowledge or tools and equipment needed for the requested work.

The above Map & Plans container was torched open and then "repaired" by unknown persons. Since it sat between several other safes the "repairs" couldn't be seen until the safe was drilled open at a later date leaving the customer the added expense of having to replace it besides the safe opening costs.

GSA Approved Map & Plans Repair---NOT!

GSA Approved Map & Plans Repair---NOT!

GSA Approved Map & Plans Repair---NOT!

Another pic of a Mosler Class 5 Map and Plans container having been torched open and then "Repaired" by installing a steel plate to fill the torched area. This safe could have originally been opened properly with a single 1/4" hole, repaired and then placed back into service. Unfortunately for this Map and Plans safe it was off to the scrap metal recycler.

Replacement costs for this type of safe is some cases may be as high as ten to twenty thousand dollars, or more, not including shipping and installation costs and the set-up time involved not to mention the time waiting for your replacement to arrive.

Drawer Heads are NOT Repairable

GSA Approved Map & Plans Repair---NOT!

Properly Opened and Repaired GSA Equipment

This GSA Approved security file's control drawer bolts were cut through with a hole saw by an unknowing locksmith and then repaired by welding them back together along with the face of the drawer. This is not allowed according to Fed-Std-809C which provides safe opening and repair procedures for DoD and DoE safes and vault doors.

If this was a newer "Red Label" security file the drawer face could have been replaced.

But, since this is actually an older "Black Label" security file it cannot be replaced or repaired due to the damage caused by the locksmith.

Properly Opened and Repaired GSA Equipment

Properly Opened and Repaired GSA Equipment

Properly Opened and Repaired GSA Equipment

After drilling open a GSA Approved security container or vault door it must be repaired according to Federal Standard 809C which includes inserting specially manufactured carbide pins welded into place on both sides. After grinding flush the weld and puttying the imperfections the door or drawer must then be painted to match the container.

A Properly Repaired Armory Vault Door

Properly Opened and Repaired GSA Equipment

A Properly Repaired Armory Vault Door

Here's an example of a properly opened and repaired GSA Approved vault door. With handles and information labels taped off along with the vault door frame edges this door was painted the proper color for Class 5 Armory vault doors. Grey is the only color allowed to be used on GSA Approved Armory vault doors.

New Combination Lock Installed

Properly Opened and Repaired GSA Equipment

A Properly Repaired Armory Vault Door

After allowing the paint to dry a new Sargent & Greenleaf mechanical combination lock has been installed meeting Federal Specification

FF-L-2937. One last item to complete before this door is within specs: Since the GSA Approved label is missing the Armory vault door must now be inspected and the GSA label replaced if it passes. Only a currently certified GSA Inspector can replace the GSA label. Dave LaBarge has been a GSA Safe and Vault Inspector since 2003.

GSA Safe and Vault Pics and Info

After drilling open a Mosler Armory vault door with defective lock. It was repaired to Fed-Std-809C specs and a S&G 2937 mechanical lock installed.

GSA Related Manufacturer's Factory Certifications

GSA Certified Safe and Vault Technician course with training by MBA USA dated 2010.

GSA related info:

We are registered with SAM, the System for Awards Management

DUNS# 616162061

CAGE CODE 3LRM0

NAICS Code 561622